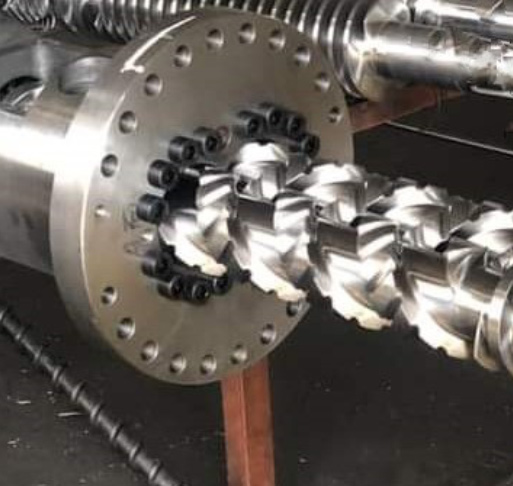

Shiva Extrusion Technique Is also offer Parallel Twin Screw & Barrels Which Responds anticorrosion & wear resistant with high quality & high performance rate with Tungsten Carbide Coating.

Twin-screw Extruder and short distance between screws are better than other types, because of their high capacity and good thermal and mechanical stress.

Screw & Barrel range from Ø25mm To Ø200mm and Length up to 6000mm.

Polymer material can be sheared & compressed more softly in screw.

The twin-screw are more effective than other types, because of their high capacity and good thermal and mechanical stress.

The powder mixing with chemical additives and melting with thermal and mechanical energy in three zones (feed, compression and metering zone) and because of gear pump and screw's pressure, converting to final product in latest plate.

Wc-10 tungsten carbide alloy, with the characteristics of high hardness, high hard-wearing & corrosion resistance, & high temperature resistance , the hardness of alloy layer reaches HRC 60-65, thus the service life of 5-8 times longer than nitride one. It is suitable for Processing PVC Pipes, Sheets , Building Plastic Template , hanging plate & other engineering plastics.

Grade A Screw : The base material is SKD61, Din 1.8519 or 1.8550, with the hardening then nitriding, the hardness of screw can reach HRC 60-65, thus having the characteristics of high wearing & corrosion Resistance.

Grade B Screw : The base material is 38CrMoAIa, the screw flight through the high temperature Ni-based alloy powder, the surface hardness can reach HRC 58-62, thus having the characteristics of highwearing & corrosion Resistance.